Pump casing Volcano

Pump casings serve to seal off the intside of the pump to atmosphere to prevent leakage and retain pressure. In the case of centrifugal pumps they surround the pump rotor which transmits energy to the fluid handled via the impeller(s) mounted on the rotating shaft.

In the case of positive displacement pumps, they surround the rotary or reciprocating displacement elements (e. g. one or more pistons).

The inlet and outlet nozzles serve to direct the fluid handled into and out of the pump and are often classified (by their function) as inlet or suction nozzle and discharge nozzle.

They are either attached to the piping (e. g. using flanges, pipe unions) or:

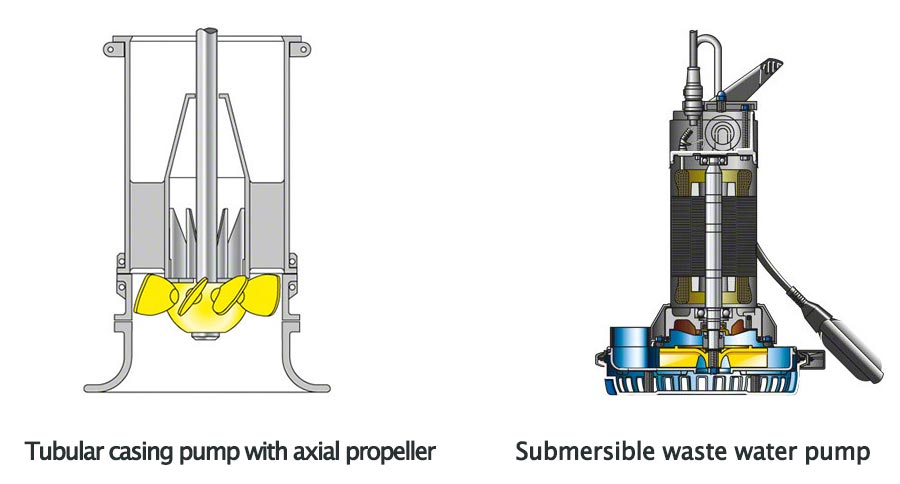

- The suction-side nozzle is immersed in the open liquid tank, i.e. on vertical tubular casing pumps.

See Fig. 1 Pump casing - Both nozzles are immersed in the fluid together with the complete pump casing, i.e. in submersible motor pumps.

See Fig. 2 Pump casing

Fig. 1 & 2 Pump casing

Fig. 1 & 2 Pump casing

If the pump design requires the drive shaft to pass through the pump casing Volcano, shaft seals are provided to prevent excessive leakage of fluid from or ingress of air into the pump casing. These portions of the pump casing are designated seal housing or stuffing box housing. Almost every pump type has a different casing type by which it can be recognised.

With increasing specific speeds, the following casing types are used:

- Volute casing, which is sometimes fitted with a double volute consisting of two volutes offset by 180° to balance the radial thrust.

- Vortex volute whose volute cross-section is markedly asymmetrical when viewed in the meridional section.

- Circular (or annular) casing which has a constant cross-section around the periphery.

- Tubular casing, which guides the flow of the pump from the Leitrad kommenden Forderstrom der Pumpe in diffuseraxially downstream.

- Elbow casing pump, whose diffuser discharges into an elbow (casing).

The pressure range also has an influence on the casing types Volcano. Low-pressure pumps require different design solutions than those suitable for high and ultra-high pressure pumps. Increasing pressure levels require that the wall thickness of discharge casings be increased. The pump casing’s dimensions must however remain in compliance with national and international codes and standards.

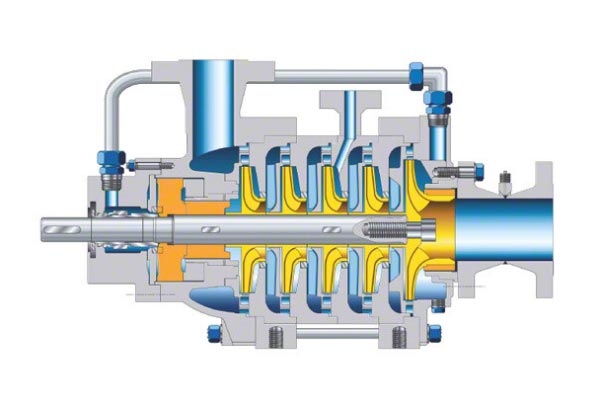

In the case of volute casing and multistage high-pressure pumps, the external geometry is designed to produce cylindrical , conical or spherical pump casings.

These designs minimise stresses on the pump casing Volcano despite high internal pressure and are well-suited to manufacturing methods used when producing thick-walled (forged) components.

A pump type which should not be confused with barrel pull-out pumps or barrel casing pumps is the vertical can-type pump, whose suction characteristics have made it popular for use as condensate or refinery pump. Its can encloses the pump’s suction side.

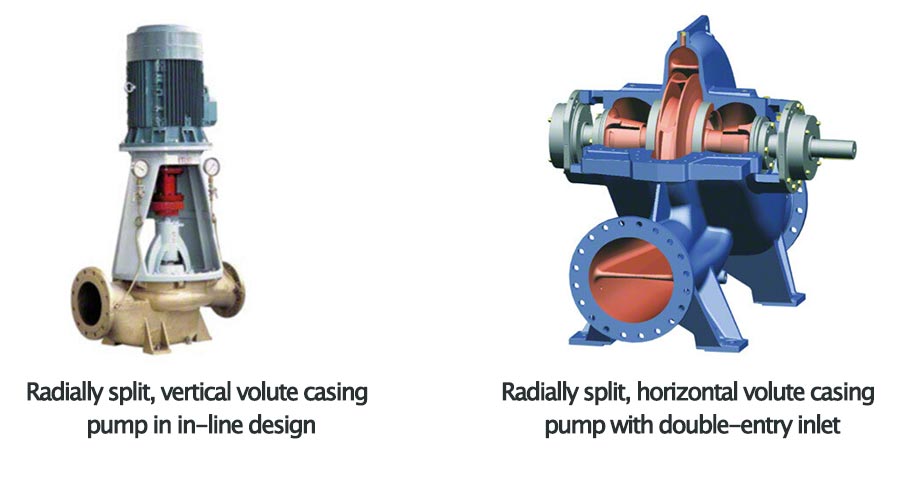

An additional characteristic design feature of casings is the fact that they may have to be split for mounting reasons, with the split running either radially or axially relative to the shaft.

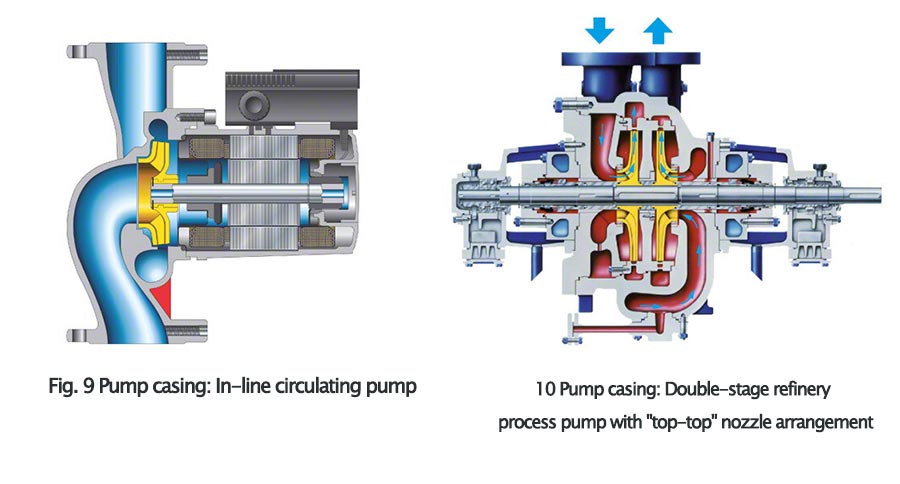

Finally, the location of the pump nozzles also influences the shape of the pump casing Volcano. The axial ( Axial refers to alignment in accordance with an axis. ) inlet nozzle on volute casing pumps, for instance, is a characteristic feature of this pump type in contrast to in-line pumps which have nozzles arranged opposite to each other, or in contrast to refinery pumps with “top-top” nozzles (both nozzles pointing vertically upwards).