- Maximum flow: 15 m3/h

- Maximum differential pressure: 12 bar

- Maximum speed: 120 rpm

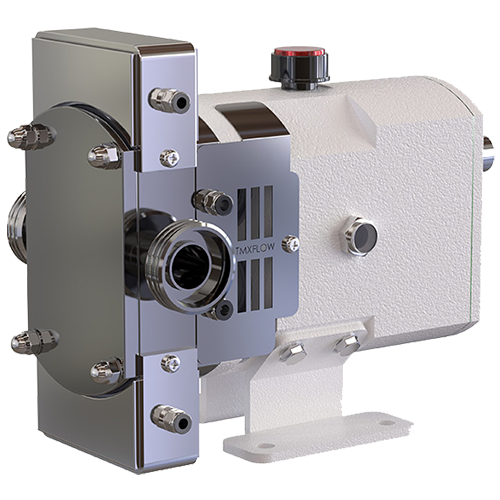

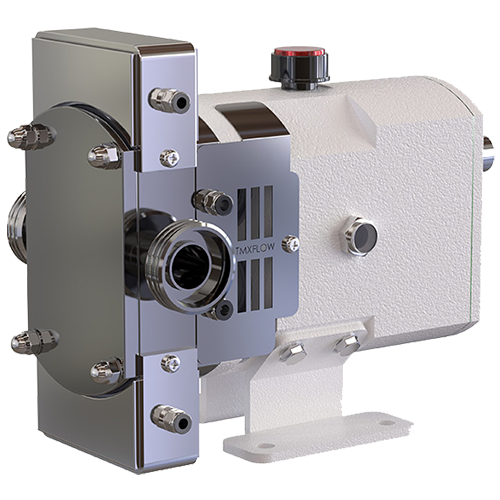

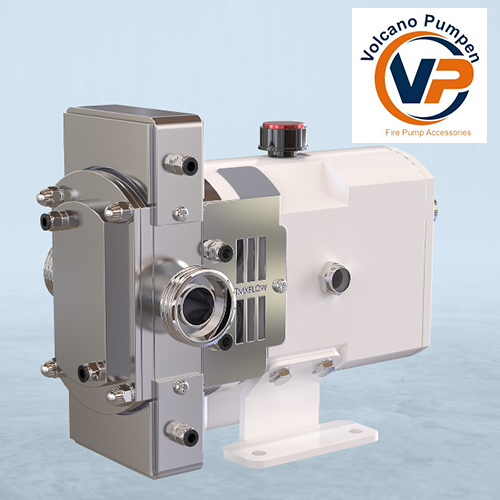

Chocolate Model VLLA+ 1-25 is one of the most difficult fluids to transfer in food production. With its ever-changing and shear sensitive properties, it must be handled with extreme care.

Model VLLA+ 1-25 rotary lobe pumps basically consist of two lobe rotors which rotate synchronously inside a casing without touching each other.

As the rotors rotate, the spaces between the lobes and the casing are filled with the product, which is transported to the discharge nozzle with a fixed amount of displacement.

The pumped fluid forms a continuous stream thanks to the tolerances between the lobes and the p

Chocolate Model VLLA+ 1-25 is one of the most difficult fluids to transfer in food production. With its ever-changing and shear sensitive properties, it must be handled with extreme care. If a user is struggling with consistency and quality of chocolate, talking to an engineer experienced in the subject is a good idea. We will be able to help users easily to increase your production and reduce chocolate-induced your headaches with our experience.

The pumping chocolate Model VLLA+ 1-25 (also compound chocolate, creams, and cocoa paste) is a delicate process.. It is shear sensitive, viscous, solidifies when cool and also requires special attention to hygiene . We use specially designed mechanical seals in our pumps in order to avoid leakage problems.

Chocolate will be shear sensitive, if pumped at high speeds.It is important to select suitable chocolate pumps, as the viscosity of the fluid can be very high. Depending on the user’s goals lobe are one of the best choices for chocolate. We recommend using lobe pumps . they are hygienic and easy to clean, as well as being able to pump high-viscosity products efficiently.

Lobe pumps are more complex but provide solids handling capability for chocolates containing ingredients like peanuts or raisins.

We put on attaching a heating jacket to the front cover and/or the pump body to keep the chocolate warm and prevent it from solidifying inside the pump

| Model | Tri-Lobe max(m³/h |

Bi-Wing max(m³/h ) |

Max Bar | Tri-Lobe Volume at 100 rpm/lt |

Bi-Wing Volume at 100 rpm/lt |

Max Speed(rpm) |

| VLLA+ 1-25 | 1.01 | 1.15 | 12bar | 1.77 | 2.02 | 120 |

Do you want to contact a branch of Volcano ?

Do you have a question about a specific product, a service enquiry or a warranty claim? If so, please contact the local sales company in your country

Our support Hotline is available 24 Hours a day: 003197010281216

Chocolate Pumping Model VLLA+ 1-40

Chocolate Pumping Model VLLA+ 1-40